Questões de Inglês - Pronomes | Pronouns para Concurso

Foram encontradas 488 questões

Mrs. Joy: is your full name, please? Mr. Smith: Thomas Wilson. Mrs. Joy: are you from? Mr. Smith: Canada. Mrs. Joy: were you born? Mr. Smith: I was born on March 7, 1956. Mrs. Joy: did you know about our job offer? Mr. Smith: Through the ad you put in the newspaper.

Internet: <https://www.nytimes.com/>

Internet: <https://www.nytimes.com/>

The Operations Function

Although somewhat ‘invisible’ to the marketplace the operations function in a typical company accounts for well over half the employment and well over half the physical assets. That, in itself, makes the operations function important. In a company’s organization chart, operations often enjoys parity with the other major business functions: marketing, sales, product engineering, finance control (accounting), and human resources (personnel, labor relations). Sometimes, the operations function is organized as a single entity which stretches out across the entire company, but more often it is embedded in the district, typically product-defined divisions into which most major companies are organized.

In many service businesses, the operations function is typically more visible. Service businesses are often organized into many branches, often with geographic responsibilities – field offices, retail outlets. In such tiers of the organization, operations are paramount.

The operations function itself is, often divided

.................two major groupings .................tasks:

line management and support services. Line management generally refers.................those managers directly concerned................the manufacture of the product or the delivery of the service. They are the ones who are typically close enough to the product or service that they can ‘touch’ it. Line management supervises the hourly, blue-collar workforce. In a manufacturing company, line management frequently extends to the stockroom (where material, parts, and semi-finished products – termed ‘work-in-process inventory – are stored), materials handling, the tool room, maintenance, the warehouse (where finished goods are stored), and distribution, as well as the so-called ‘factory floor’. In a service operation, what is considered line management can broaden considerably. Often, order-taking roles, in addition to orderfilling roles, are supervised by service line managers.

Support services for line management’s operations can be numerous. Within a manufacturing environment, support services carry titles such as quality control, production planning and scheduling, purchasing, inventory control, production control (which determines the status of jobs in the factory and what to do about jobs that may have fallen behind schedule), industrial engineering (which is work methods oriented), manufacturing engineering (which is hardware-oriented), on-going product engineering, and field service. In a service environment, some of the same roles are played but sometimes under vastly different names.

Thus, the managers for whom operational issues are central can hold a variety of titles. In manufacturing, the titles can range from vice-president – manufacturing, works manager, plant manager, and similar titles at the top of the hierarchy, through such titles as manufacturing or production manager, general superintendent, department manager, materials manager, director of quality control, and down to general foreman or foreman. Within service businesses, ‘operations manager’ is sometimes used but frequently the title is more general – business manager, branch manager, retail manager, and so on.

SCHMENNER, Roger W. Production/Operations Management.

5th Edition. Prentice-Hall, 1993.

The Operations Function

Although somewhat ‘invisible’ to the marketplace the operations function in a typical company accounts for well over half the employment and well over half the physical assets. That, in itself, makes the operations function important. In a company’s organization chart, operations often enjoys parity with the other major business functions: marketing, sales, product engineering, finance control (accounting), and human resources (personnel, labor relations). Sometimes, the operations function is organized as a single entity which stretches out across the entire company, but more often it is embedded in the district, typically product-defined divisions into which most major companies are organized.

In many service businesses, the operations function is typically more visible. Service businesses are often organized into many branches, often with geographic responsibilities – field offices, retail outlets. In such tiers of the organization, operations are paramount.

The operations function itself is, often divided

.................two major groupings .................tasks:

line management and support services. Line management generally refers.................those managers directly concerned................the manufacture of the product or the delivery of the service. They are the ones who are typically close enough to the product or service that they can ‘touch’ it. Line management supervises the hourly, blue-collar workforce. In a manufacturing company, line management frequently extends to the stockroom (where material, parts, and semi-finished products – termed ‘work-in-process inventory – are stored), materials handling, the tool room, maintenance, the warehouse (where finished goods are stored), and distribution, as well as the so-called ‘factory floor’. In a service operation, what is considered line management can broaden considerably. Often, order-taking roles, in addition to orderfilling roles, are supervised by service line managers.

Support services for line management’s operations can be numerous. Within a manufacturing environment, support services carry titles such as quality control, production planning and scheduling, purchasing, inventory control, production control (which determines the status of jobs in the factory and what to do about jobs that may have fallen behind schedule), industrial engineering (which is work methods oriented), manufacturing engineering (which is hardware-oriented), on-going product engineering, and field service. In a service environment, some of the same roles are played but sometimes under vastly different names.

Thus, the managers for whom operational issues are central can hold a variety of titles. In manufacturing, the titles can range from vice-president – manufacturing, works manager, plant manager, and similar titles at the top of the hierarchy, through such titles as manufacturing or production manager, general superintendent, department manager, materials manager, director of quality control, and down to general foreman or foreman. Within service businesses, ‘operations manager’ is sometimes used but frequently the title is more general – business manager, branch manager, retail manager, and so on.

SCHMENNER, Roger W. Production/Operations Management.

5th Edition. Prentice-Hall, 1993.

‘…line management frequently extends to the stockroom…’ and ‘…management can broaden considerably.’

Are being used in these sentences as examples of:

Fonte: Murphy Raymond: English Grammar in Use (1997).

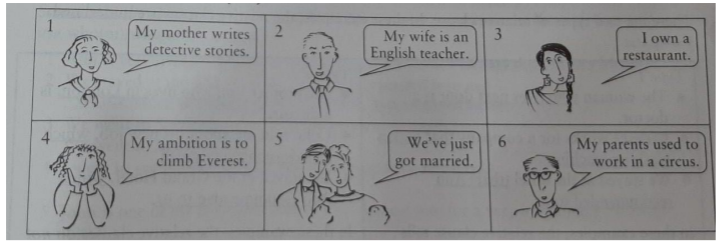

Fonte: Murphy Raymond: English Grammar in Use (1997). Later you tell a friend about the people you met. Complete the sentences using WHO or WHOSE. 1 - I met somebody... 2 - I met Jacob... 3 - I met Mary... 4 - I met Carol... 5 - I met Jhon and Ann.. 6 - I met Enzo...

A Brief and Simplified Description of Papermaking

The paper we use today is created from individual wood fibers that are first suspended in water and then pressed and dried into sheets. The process of converting the wood to a suspension of wood fibers in water is known as pulp making, while the manufacture of the dried and pressed sheets of paper is formally termed papermaking. The process of making paper has undergone a steady evolution, and larger and more sophisticated equipment and better technology continue to improve it.

The Wood yard and Wood rooms

The process at Androscogging began with receiving wood in the form of chips or of logs 4 or 8 feet in length. From 6 AM to 10 PM a steady stream of trucks and railroad cars were weighted and unloaded. About 40 percent were suplied by independents who were paid by weight their logs. The mill also received wood chips from lumber mills in the area. The chips and logs were stored in mammoth piles with separate piles for wood of different species (such as pine, spruce, hemlock).

When needed, logs were floated in flumes......(1).....the wood yard.....(2).....one of the mill’s three wood rooms. There, bark was rubbed......(3)........in long, ribbed debarking drums by tumbling the logs against one another. The logs then fell into a chipper;......(4)......seconds a large log was reduced to a pile of chips approximately 1 inch by 1 inch by 1/4 inch.

The chips were stored in silos. There were separate silos for softwoods (spruce, fir, hemlock, and pine) and hardwoods (maple, oak, beech, and birch). This separate and temporary storage of chips permitted the controlled mixing of chips into the precise recipe for the grade of paper being produced.

The wood chips were then sorted through large, flat vibrating screens. Oversized chips were rechipped, and ones that were too small were collected for burning in the power house. (The mill provided approximately 20 percent of all its own steam and electricity needs from burning waste. An additional 50 percent of total electricity needs was produced by harnessing the river for hydroelectric power.)

Once drawn from the silo into the digesters, there was no stopping the flow of chips into paper.

Pulpmaking

The pulp made at Androscoggin was of two types: Kraft pulp (produced chemically) and ground wood pulp (produced mechanically). Kraft pulp was far more important to the high quality white papers produced at Androscoggin, accounting for 80 percent of all the pulp used. Kraft pulp makes strong paper. (Kraft is German for strength. A German invented the Kraft pulp process in 1884.) A paper’s strength generally comes from the overlap and binding of long fibers of softwood; only chemically was it initially possible to separate long wood fibers for suspension in water. Hardwood fibers are generally smaller and thinner and help smooth the paper and make it less porous.

The ground wood pulping process was simpler and less expensive than the Kraft process. It took high quality spruce and fir logs and pressed them continuously against a revolving stone that broke apart the wood’s fibers. The fibers, however, were smaller than those produced by the Kraft process and, although used to make newsprint, were useful at Androscoggin in providing “fill” for the coated publication gloss papers of machines 2 and 3, as will be described later.

(A)The chemical Kraft process worked by dissolving the lignin that bonds wood fibers together. (B) It did this in a tall pressure cooker, called a digester, by “cooking” the chips in a solution of caustic soda (NaOH) and sodium sulfide (Na2S), which was termed the “white liquor.” (C)The two digesters at Androscoggin were continuous digesters; chips and liquor went into the top, were cooked together as they slowly settled down to the bottom, and were drawn off the bottom after about three hours. (D) By this time, the white liquor had changed chemically to “black liquor’’; the digested chips were then separated from this black liquor. (E)

In what was known as the “cold blow” process, the hot, pressurized chips were gradually cooled and depressurized. A “cold liquor’’ (170°F) was introduced to the bottom of the digester and served both to cool and to transport the digested chips to a diffusion washer that washed and depressurized the chips. Because so much of the lignin bonding the fibers together had been removed, the wood fiber in the chips literally fell apart at this stage.

The black liquor from the digester entered a separate four-step recovery process. Over 95 percent of the black liquor could be reconstituted as white liquor, thereby saving on chemical costs and significantly lowering pollution. The four-step process involved (1) washing the black liquor from the cooked fiber to produce weak black liquor, (2) evaporating the weak black liquor to a thicker consistency, (3) combustion of this heavy black liquor with sodium sulfate (Na2SO4 ), and redissolving the smelt, yielding a “green liquor” (sodium carbonate + sodium sulfide), and (4) adding lime, which reacted with the green liquor to produce white liquor. The last step was known as causticization.

Meanwhile, the wood-fiber pulp was purged of impurities like bark and dirt by mechanical screening and by spinning the mixture in centrifugal cleaners. The pulp was then concentrated by removing water from it so that it could be stored and bleached more economically.

By this time, depending on the type of pulp being made, it had been between 3 1/2 and 5 hours since the chips had entered the pulp mill.

All the Kraft pulp was then bleached. Bleaching took between 5 and 6 hours. It consisted of a three-step process in which (1) a mix of chlorine (Cl2 ) and chlorine dioxide (CIO2 ) was introduced to the pulp and the pulp was washed; (2) a patented mix of sodium hydroxide (NaOH), liquid oxygen, and hydrogen peroxide (H2 O2 ) was then added to the pulp and the pulp was again washed; and (3) chlorine dioxide (ClO2 ) was introduced and the pulp washed a final time. The result was like fluffy cream of wheat. By this time the pulp was nearly ready to be made into paper.

From the bleachery, the stock of pulp was held for a short time in storage (a maximum of 16 hours) and then proceeded through a series of blending operations that permitted a string of additives (for example, filler clay, resins, brighteners, alum, dyes) to be mixed into the pulp according to the recipe for the paper grade being produced. Here, too, “broke” (paper wastes from the mill itself) was recycled into the pulp. The pulp was then once again cleaned and blended into an even consistency before moving to the papermaking machine itself.

It made a difference whether the broke was of coated

or uncoated paper, and whether it was white or colored. White, uncoated paper could be recycled immediately. Colored, uncoated paper had to be rebleached.

Coated papers, because of the clays in them, could not

be reclaimed.

A Brief and Simplified Description of Papermaking

The paper we use today is created from individual wood fibers that are first suspended in water and then pressed and dried into sheets. The process of converting the wood to a suspension of wood fibers in water is known as pulp making, while the manufacture of the dried and pressed sheets of paper is formally termed papermaking. The process of making paper has undergone a steady evolution, and larger and more sophisticated equipment and better technology continue to improve it.

The Wood yard and Wood rooms

The process at Androscogging began with receiving wood in the form of chips or of logs 4 or 8 feet in length. From 6 AM to 10 PM a steady stream of trucks and railroad cars were weighted and unloaded. About 40 percent were suplied by independents who were paid by weight their logs. The mill also received wood chips from lumber mills in the area. The chips and logs were stored in mammoth piles with separate piles for wood of different species (such as pine, spruce, hemlock).

When needed, logs were floated in flumes......(1).....the wood yard.....(2).....one of the mill’s three wood rooms. There, bark was rubbed......(3)........in long, ribbed debarking drums by tumbling the logs against one another. The logs then fell into a chipper;......(4)......seconds a large log was reduced to a pile of chips approximately 1 inch by 1 inch by 1/4 inch.

The chips were stored in silos. There were separate silos for softwoods (spruce, fir, hemlock, and pine) and hardwoods (maple, oak, beech, and birch). This separate and temporary storage of chips permitted the controlled mixing of chips into the precise recipe for the grade of paper being produced.

The wood chips were then sorted through large, flat vibrating screens. Oversized chips were rechipped, and ones that were too small were collected for burning in the power house. (The mill provided approximately 20 percent of all its own steam and electricity needs from burning waste. An additional 50 percent of total electricity needs was produced by harnessing the river for hydroelectric power.)

Once drawn from the silo into the digesters, there was no stopping the flow of chips into paper.

Pulpmaking

The pulp made at Androscoggin was of two types: Kraft pulp (produced chemically) and ground wood pulp (produced mechanically). Kraft pulp was far more important to the high quality white papers produced at Androscoggin, accounting for 80 percent of all the pulp used. Kraft pulp makes strong paper. (Kraft is German for strength. A German invented the Kraft pulp process in 1884.) A paper’s strength generally comes from the overlap and binding of long fibers of softwood; only chemically was it initially possible to separate long wood fibers for suspension in water. Hardwood fibers are generally smaller and thinner and help smooth the paper and make it less porous.

The ground wood pulping process was simpler and less expensive than the Kraft process. It took high quality spruce and fir logs and pressed them continuously against a revolving stone that broke apart the wood’s fibers. The fibers, however, were smaller than those produced by the Kraft process and, although used to make newsprint, were useful at Androscoggin in providing “fill” for the coated publication gloss papers of machines 2 and 3, as will be described later.

(A)The chemical Kraft process worked by dissolving the lignin that bonds wood fibers together. (B) It did this in a tall pressure cooker, called a digester, by “cooking” the chips in a solution of caustic soda (NaOH) and sodium sulfide (Na2S), which was termed the “white liquor.” (C)The two digesters at Androscoggin were continuous digesters; chips and liquor went into the top, were cooked together as they slowly settled down to the bottom, and were drawn off the bottom after about three hours. (D) By this time, the white liquor had changed chemically to “black liquor’’; the digested chips were then separated from this black liquor. (E)

In what was known as the “cold blow” process, the hot, pressurized chips were gradually cooled and depressurized. A “cold liquor’’ (170°F) was introduced to the bottom of the digester and served both to cool and to transport the digested chips to a diffusion washer that washed and depressurized the chips. Because so much of the lignin bonding the fibers together had been removed, the wood fiber in the chips literally fell apart at this stage.

The black liquor from the digester entered a separate four-step recovery process. Over 95 percent of the black liquor could be reconstituted as white liquor, thereby saving on chemical costs and significantly lowering pollution. The four-step process involved (1) washing the black liquor from the cooked fiber to produce weak black liquor, (2) evaporating the weak black liquor to a thicker consistency, (3) combustion of this heavy black liquor with sodium sulfate (Na2SO4 ), and redissolving the smelt, yielding a “green liquor” (sodium carbonate + sodium sulfide), and (4) adding lime, which reacted with the green liquor to produce white liquor. The last step was known as causticization.

Meanwhile, the wood-fiber pulp was purged of impurities like bark and dirt by mechanical screening and by spinning the mixture in centrifugal cleaners. The pulp was then concentrated by removing water from it so that it could be stored and bleached more economically.

By this time, depending on the type of pulp being made, it had been between 3 1/2 and 5 hours since the chips had entered the pulp mill.

All the Kraft pulp was then bleached. Bleaching took between 5 and 6 hours. It consisted of a three-step process in which (1) a mix of chlorine (Cl2 ) and chlorine dioxide (CIO2 ) was introduced to the pulp and the pulp was washed; (2) a patented mix of sodium hydroxide (NaOH), liquid oxygen, and hydrogen peroxide (H2 O2 ) was then added to the pulp and the pulp was again washed; and (3) chlorine dioxide (ClO2 ) was introduced and the pulp washed a final time. The result was like fluffy cream of wheat. By this time the pulp was nearly ready to be made into paper.

From the bleachery, the stock of pulp was held for a short time in storage (a maximum of 16 hours) and then proceeded through a series of blending operations that permitted a string of additives (for example, filler clay, resins, brighteners, alum, dyes) to be mixed into the pulp according to the recipe for the paper grade being produced. Here, too, “broke” (paper wastes from the mill itself) was recycled into the pulp. The pulp was then once again cleaned and blended into an even consistency before moving to the papermaking machine itself.

It made a difference whether the broke was of coated

or uncoated paper, and whether it was white or colored. White, uncoated paper could be recycled immediately. Colored, uncoated paper had to be rebleached.

Coated papers, because of the clays in them, could not

be reclaimed.

“The ground wood pulping process was simpler and less expensive than the Kraft process. It took high quality spruce and fir logs and pressed them continuously against a revolving stone that broke apart the wood’s fibers.”

1. the word ‘simpler’ is an adjective in the superlative form. 2. the word ‘them’ is an object pronoun. 3. the tense used in ’took’, is simple past of a regular verb. 4. the word ‘that’ can be replaced by ‘which’ without changing its meaning.

Choose the alternative which presents the correct ones:

- You should laugh, my dear. Because immortality is my lot or my dowry, or as best name there is. I will live perpetually in my great book. Those who, however, do not can read, charlatan Quincas Borba to the dog, and ...

- My poor friend! my good friend! my only friend!

- Unique!

Gombrich, E. H. The Story of Art. Phaidon, 16th.

Ed. 1995. pp.65-6, with adaptations.

The two instances of “whom” in “whom he worshipped and whom he had represented” (lines 31 and 32) can, in an informal context, be replaced with who, but “whom” and “who” play very distinct grammar roles in a sentence.

Munoz, Maricela. “Diplomacy in times of COVID-19.” Diplo (blog). Jul.

16, 2020. Accessed Sep. 10, 2020. https://www.diplomacy.edu/blog, with

adaptations.

In line 14, the word “one” is used as a pronoun for the antecedent “a whole new environment” (line 13).

I. The man ___lives next door is a lawyer. II. Did you read the book ___ we told you? III. The movie contained many scenes ___ shocked the audience.. IV. The girl ___ brother is arrested doesn’t say anything about it. V. Do you see the animal ___ is on the tree?

Alternatives:

Read the text below:

“Washington was born to a moderately prosperous Virginian family of colonial planters and slaveholders. He had early educational opportunities, learned mathematics, and soon launched a successful career as a surveyor which enabled him to make significant land investments. He then became a senior leader of the Virginia militia and played major roles in the French and Indian War. He was appointed commander-in-chief of the Continental Army during the Revolutionary War, leading an allied campaign to victory at the Siege of Yorktown which ended the war. His devotion to Republicanism and revulsion for tyrannical power impelled him to decline further authority after victory, and he resigned as commander-in-chief in 1783.”

How many personal pronouns are there in this text?

Which option best completes the paragraph below?

As with the Anglo-Saxon and Norman settlers of centuries past, the languages spoken by today’s ethnic communities have begun to have an impact on the everyday spoken English of other communities. For instance, many young people, regardless of _________ ethnic background, now use the black slang terms, nang (‘cool,’) and diss (‘insult’ — from ‘disrespecting’) or words derived from Hindi and Urdu, such as chuddies (‘underpants’) or desi (‘typically Asian’). Many also use the all-purpose tag-question, innit — as in statements such as you’re weird, innit. This feature has been variously ascribed to the British Caribbean community or the British Asian community, although it is also part of a more native British tradition - in dialects in the West Country and Wales, for instance — which might explain why it appears to have spread so rapidly among young speakers everywhere.

https://www.bl.uk/learning/langlit/sounds/case-studies/minority-ethnic/

Complete each sentence using where/whom/whose/who and choose the right answer below:

I - He doesn´t know the name of the dog to.........Ispoke yesterday night.

II - A house is a place.......people live togheter.

III - A humorista is a person.......believes that all the people are happy.

IV - An elephant is an animal........children are also very big.

V - The place........we spent our days was really wonderful.

The sentences below need to be completed with where/whom/whose/who. Choose the right answer:

I - He doesn´t know the age of the girl to.........he saw saturday night.

II - A church is a place.......... people pray a lot.

III - A doctor is a person .......... care the health of people.

IV - A father is a man.......... play the children a lot.

V - The school........I studied was really fantastic.